Aluminum alloys are widely used in different industries due to their unique properties such as lightweight, high strength, and good corrosion resistance. Among these alloys, the SAE AMS4050 aluminum alloy plate/'>plate is a popular choice for the aerospace industry.

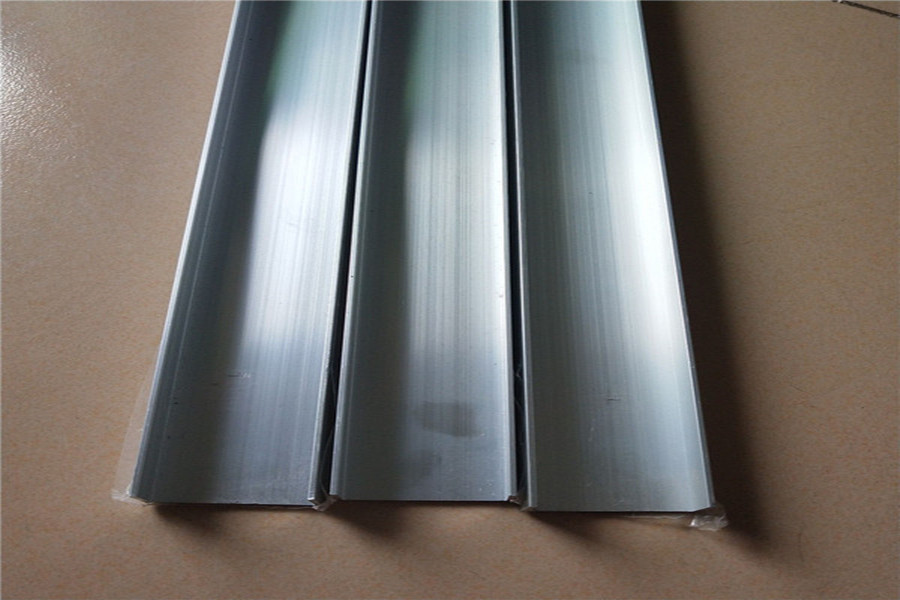

The SAE AMS4050 aluminum alloy plate is a solution heat-treated, stress-relieved, and overaged material. It is made up of 6.2% zinc, 2.3% copper, 2.2% magnesium, and 0.12% zirconium. The alloy has excellent strength and toughness at various temperatures, making it ideal for high-performance applications.

The aluminum alloy plate is also treated with Alodine. Alodine is a chromate conversion coating that offers excellent corrosion resistance for aluminum alloys. The coating also improves the adhesion of paints and other organic coatings to the aluminum surface.

The aerospace industry extensively uses aluminum alloys due to their lightweight and strength properties. The SAE AMS4050 aluminum alloy plate is a popular choice in the industry due to its strength, toughness, and corrosion resistance. The Alodine treatment further enhances the corrosion resistance of the alloy plate.

The aerospace industry uses the SAE AMS4050 aluminum alloy plate in different applications such as aircraft structures, landing gears, and other components. The high strength to weight ratio of the alloy is essential for achieving fuel efficiency and reducing carbon emissions. The alloy's corrosion resistance is crucial for protecting the components from the harsh environment of the aerospace industry.

In conclusion, the SAE AMS4050 aluminum alloy plate treated with Alodine is a popular choice in the aerospace industry. The alloy's strength, toughness, and corrosion resistance make it ideal for high-performance applications. The Alodine treatment further enhances the alloy's corrosion resistance, making it an excellent choice for aerospace components.