Changyao Refractory Material Company, a leading producer of high-temperature refractory materials, has recently introduced a state-of-the-art Hot Top Billet Casting Machine. The new machine is anticipated to revolutionize the aluminum and metal melting and casting industry by offering improved efficiency and superior product quality.

Founded in 1999, Changyao Refractory Material Company has built a sterling reputation for its expertise in manufacturing high-temperature refractory materials such as refractory bricks, aluminum silicate stopper cones, and aluminum silicate wool boards. These materials are crucial components used in aluminum and other metal melting and casting plants. Over the years, the company has established itself as a trusted and reliable provider of these essential materials to various industries.

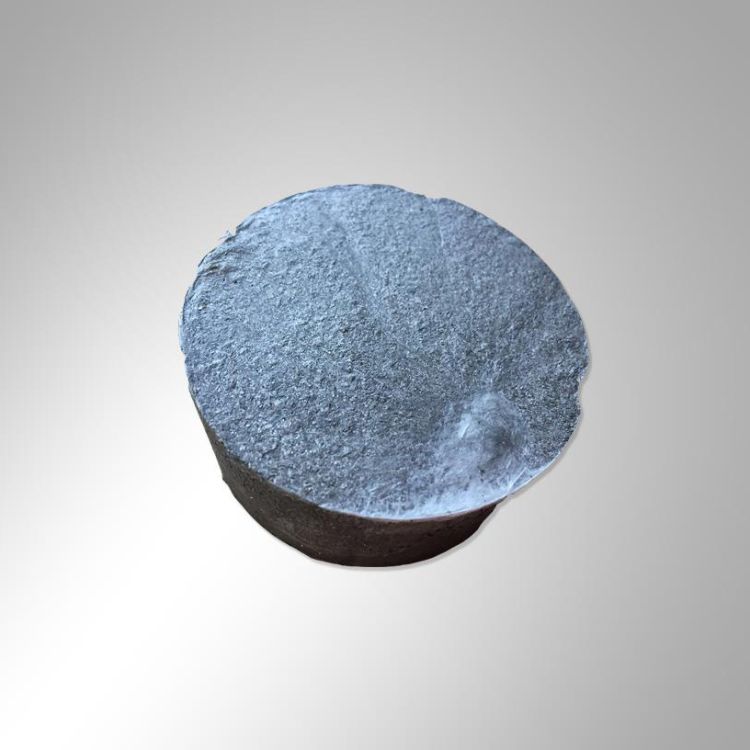

With the introduction of the Hot Top Billet Casting Machine, Changyao Refractory Material Company aims to further solidify its position as an industry leader. The new machine is designed to improve the casting process by facilitating the production of high-quality billets with enhanced efficiency and precision. This development is expected to significantly impact the production capabilities of aluminum and metal casting plants, ultimately allowing for greater output and cost-effectiveness.

The Hot Top Billet Casting Machine incorporates advanced technology to optimize the casting process. Its innovative design enables seamless and uniform filling of molds, resulting in consistently high-quality billets. The machine also boasts features that enhance safety and reduce the risk of defects or inconsistencies in the final product, further solidifying its appeal to manufacturers in the industry.

In addition to its technical capabilities, the Hot Top Billet Casting Machine is also designed with user-friendliness in mind. Its intuitive controls and user interface make it easy for operators to oversee the casting process and make adjustments as necessary. This helps streamline operations and minimize downtime, contributing to overall productivity and efficiency.

Changyao Refractory Material Company has invested significant resources into research and development to bring the Hot Top Billet Casting Machine to fruition. By leveraging its expertise in high-temperature refractory materials and understanding the unique needs of the aluminum and metal casting industry, the company has successfully engineered a solution that addresses critical challenges and sets a new standard for casting technology.

The unveiling of the Hot Top Billet Casting Machine represents a significant milestone for Changyao Refractory Material Company. As the company continues to innovate and expand its product offerings, it is poised to make a substantial impact on the aluminum and metal casting industry, serving as a catalyst for improved efficiency and product quality.

Industry experts and potential customers have expressed keen interest in the Hot Top Billet Casting Machine, recognizing its potential to elevate casting operations to new heights. With its cutting-edge capabilities and the backing of Changyao Refractory Material Company's established reputation, the machine is poised to garner widespread attention and adoption within the industry.

Changyao Refractory Material Company is committed to supporting its customers with reliable, high-quality products and innovative solutions. The introduction of the Hot Top Billet Casting Machine exemplifies the company's dedication to driving progress and enabling the success of its clients in the aluminum and metal casting sector.

In conclusion, the launch of the Hot Top Billet Casting Machine marks a significant achievement for Changyao Refractory Material Company and a pivotal moment for the aluminum and metal casting industry. With its advanced capabilities and potential to enhance efficiency and product quality, the new machine is poised to redefine the casting process and empower manufacturers to achieve new levels of success.