About This Item

Production Method:Prepare pure aluminum ingots, aluminum rare earth alloy ingots, potassium fluorotitanate, potassium fluoroborate and other raw materials according to the pre-prepared refiner ingredients; heat and melt aluminum ingots and aluminum rare earth ingots in an intermediate frequency induction furnace, and then add various raw materials; The melt starts to react at high temperature; after the reaction is completed, heat preservation and slag removal are completed, and then it is cast into an ingot or continuously cast and rolled into a wire rod. According to the above process conditions, for high-purity aluminum, columnar crystals can be eliminated. For industrial pure aluminum and various series of deformed aluminum alloys, the grain size can be refined to less than 100 μm. It can be stably reduced to below 2μm; for Al-Si alloy, the grain size can be refined to below 150-200μm. At the same time, the strength, plasticity and toughness of industrial pure aluminum and various aluminum alloys have been significantly improved. Product introduction: Features: refinement, easy to use, for aluminum alloy melt. Aluminum-titanium-boron wire is one of the most effective refiners for aluminum and aluminum alloys.Product Dispaly

Product Features

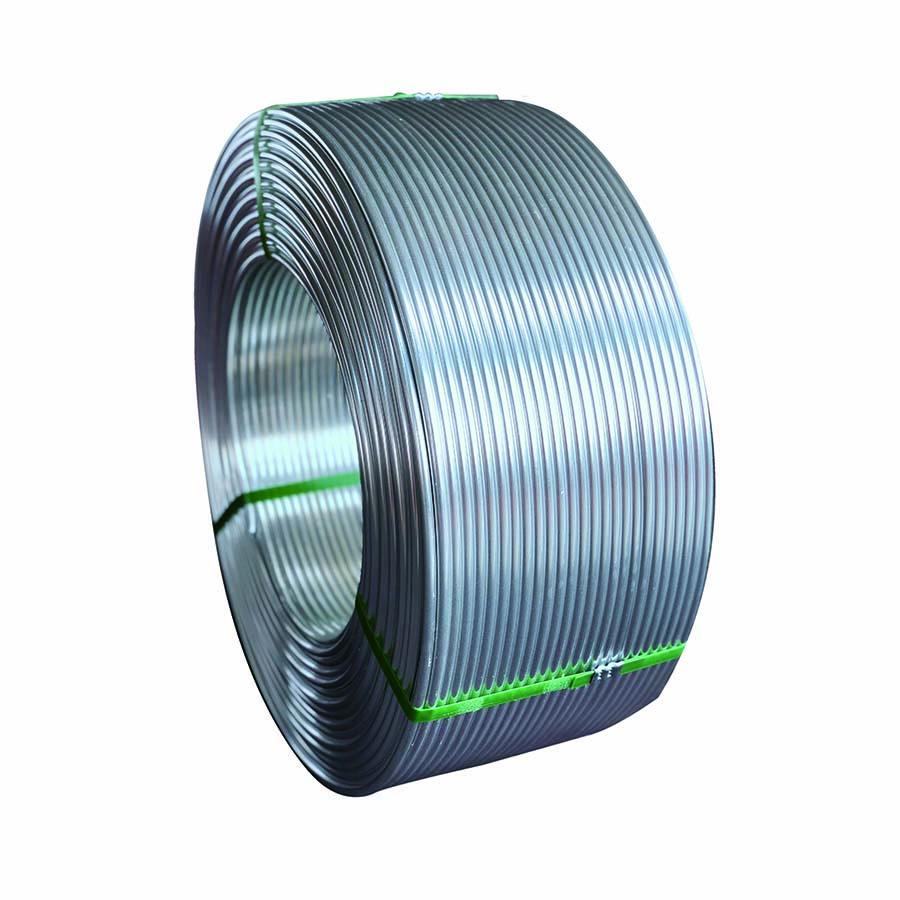

About Φ9.5mm wire, each roll is about 100 kg (170 kg), the alloy wire composition is 5%T 1%B, Content of ingredients and impurities meet the requirements of national standards GB8736-88.

Usage

(1) It is mainly suitable for grain refinement of aluminum and aluminum alloys, to improve the strength and plasticity of aluminum materials or castings, and to improve comprehensive mechanical properties; (2) Reducing the scrap rate, the surface quality, the uniformity and brightness of the oxidative coloring of the profiles; (3) It is easy to add, and there is no loss of titanium boron. Widely used in aluminum castings, aluminum profiles, aluminum cables, aluminum foil and other industries.