About This Item

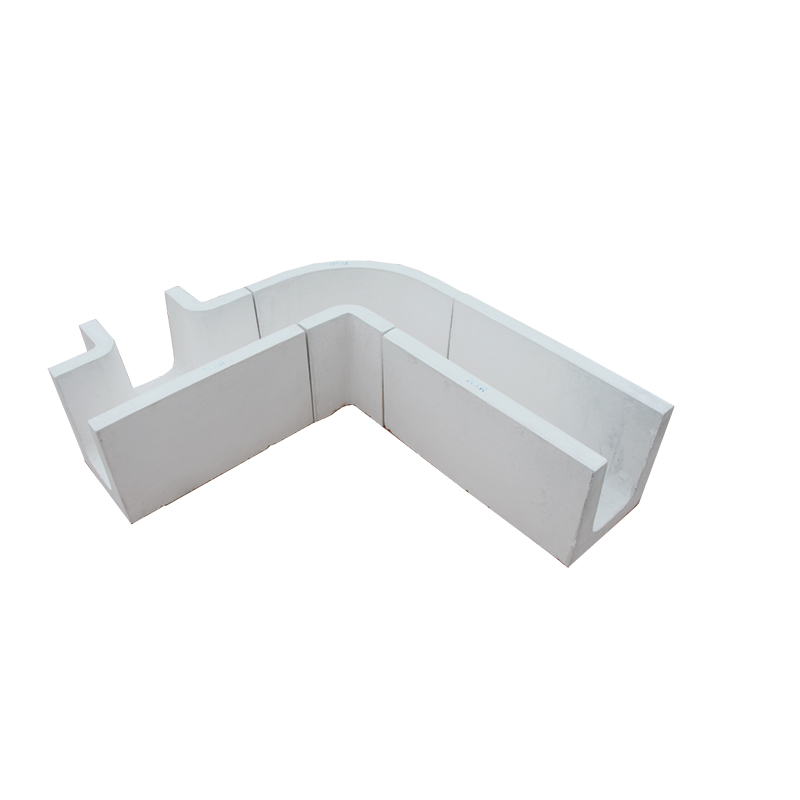

Product advantages: Good thermal insulation performance, reasonable design, prolong service life It is integrally formed with noble molten material and has high dimensional accuracy; The groove lining has high strength, erosion resistance, thermal shock resistance, and smooth surface; The lining has strong corrosion resistance to aluminum, zinc and magnesium alloys, which enhances the use effect of molten metal transfer equipment and enhances the service life of special alloys; During use, the temperature drop of the metal liquid is within 2°C per meter, it is resistant to erosion, heat shock, and the surface is smooth. The inner lining of the box adopts the advanced production process of integrally formed launder lining: greatly improving the erosion resistance and erosion resistance of the launder lining. Effectively prolong the service life of the launder lining. Used in conjunction with our boron nitride coating, the effect of non-sticking to aluminum is excellent, and the inner lining can be independently produced and supplied according to the needs. It has a lining body with a long life and adopts a new high-silicon molten material forming technology, which has strong corrosion resistance, non-sticking to aluminum, and no pollution to the aluminum liquid. The integrated launder equipment produced is installed between the furnace and the casting machine and has a dual function: conveying and holding. It is mainly used for aluminum liquid transportation between aluminum alloy precision casting aluminum melting furnaces, purification furnaces, casting platforms, degassing and filtration outside the furnace, such as aviation and transportation. Such as: computer hard disk, micron aluminum foil wool, PS board base for printing, can making material, jet turbine engine fan blade and other products.Product Dispaly