About This Item

It is Suitable for hot water, high temperature, high pressure steam, heat exchange liquid, nitrogen, organic solvent, hydrocarbon, low temperature liquid and other media. For compressors, pumps, valves, chemical instruments, meters, etc. Pressure (Mpa): 25 Temperature(℃):-200~850 Linear speed (m/s): 30PH value: 0~14 Graphite rings are divided into flexible graphite and carbon-graphite rings. Carbon-graphite rings are mainly used in the sealing of mechanical rotating parts and have the characteristics of corrosion resistance.Product Dispaly

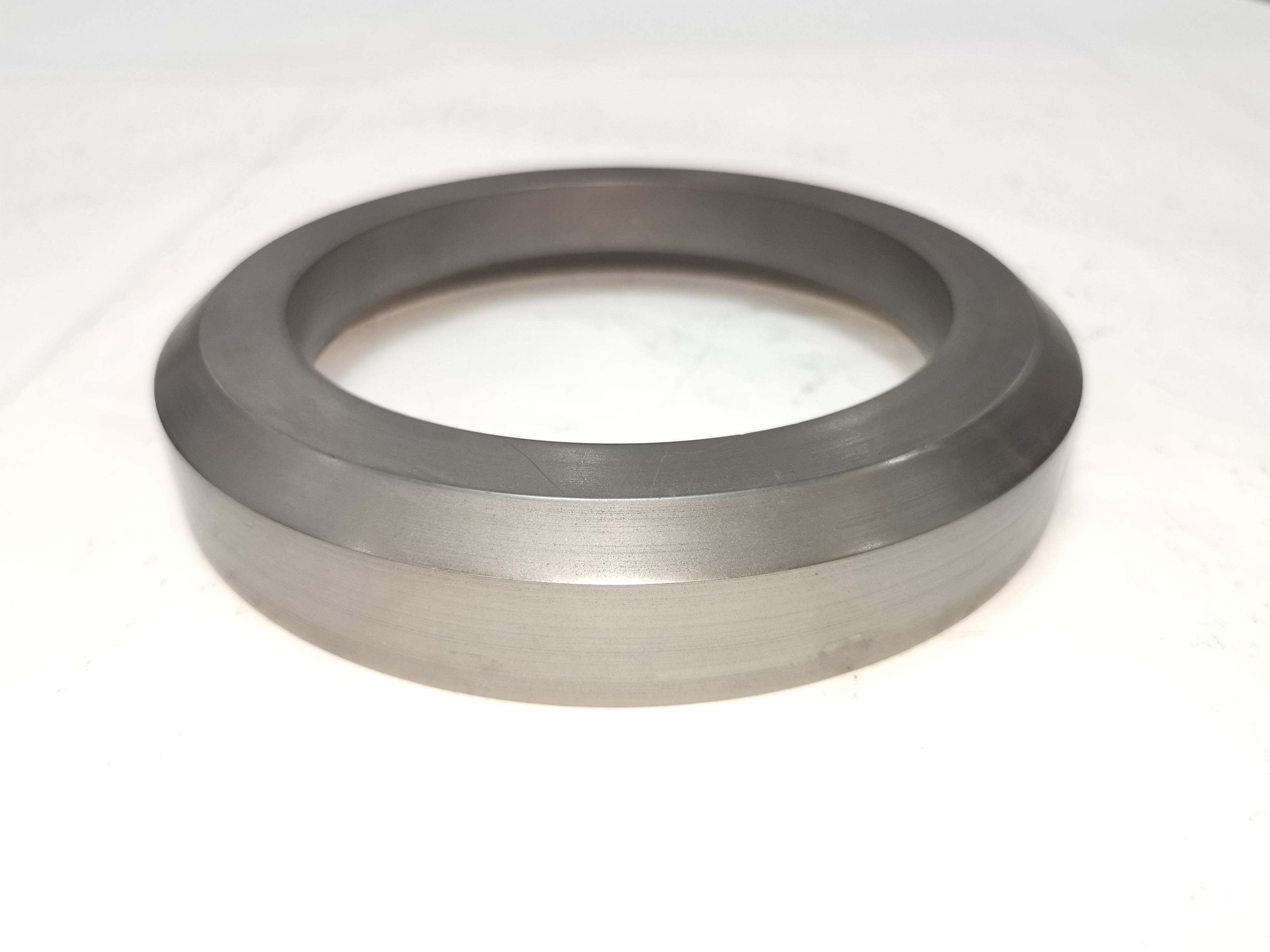

Graphite Ring Performance And Characteristics

1. The graphite ring has good self-lubrication. 2. High rebound coefficient of graphite ring. 3. The graphite ring can be cut with a 45° oblique cut according to user needs.Instructions for use of accessories

1.Select the hot-top casting equipment platform installation accessories of the corresponding specifications; 2.install the distribution plate, sleeve, adapter plate, distribution groove, and high-purity graphite ring on the upper side of the platform, and install the sleeve, adapter plate, and graphite ring on the mold. On the inside, ensure clean, no damage and no gaps. It is best to use ceramic fiber paper or ceramic fiber blanket to seal the sides and bottom, which is helpful for thermal insulation. 3.After the overall hot top casting platform is installed, evenly preheat the installed standard equipment platform to 260-350 ℃, by electricity or gas. No open flame should contact the lining body of the product, Otherwise, the crack damage that occurs shall be borne by the user. 4.remove adsorbed crystal water, Make it safe and efficient use